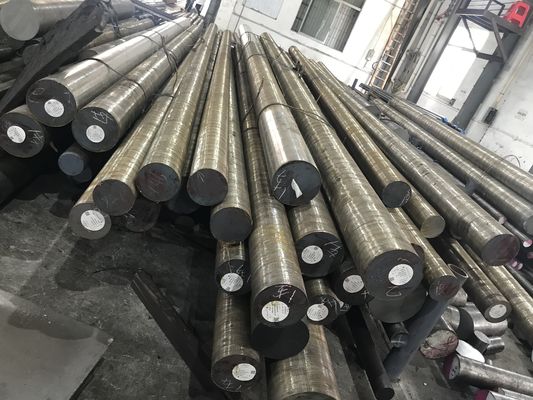

high strength 4340 alloy gear steel round bar manufactory for gearing

AISI 4340 Steel Manufacturer and Exporter supplying Round, Square, Flat, Block and Shaft etc. AISI 4340 is defined as a heat treatable low alloy steel containing 0.8% Cr, 0.2% Mo and 1.8% Ni as strengthening alloying elements. Compared with AISI 4140, it has higher strength and toughness and has very good Excellent fatigue resistance, wear resistance and atmospheric corrosion resistance. AISI 4340 is usually supplied in the quenched and tempered condition with a tensile range of 930 – 1080 Mpa and a hardness of 280 -320HB. Pre hardened and tempered 4340 can be further case hardened by flame or induction hardening and nitriding.

1.Supply Form & Size & Tolerance

| Supply Form |

Size(mm) |

Process |

Tolerance |

Round |

Φ6-Φ100 |

Cold Drawn |

Bright/Black |

Best H11 |

Φ16-Φ350 |

Hot Rolled |

Black |

-0/+1mm |

| Peeled/ground |

Best H11 |

Φ90-Φ1000 |

Hot Forged |

Black |

-0/+5mm |

| Rough Turned |

-0/+3mm |

Flat/Square/Block |

Thickness :120-800 |

Hot Forged |

Black |

-0/+8mm |

| Width:120-1500 |

Rough Machined |

-0/+3mm |

Remark:Tolerance can be customized as per requests

2.Chemical Composition

| Standard |

Grade |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Mo |

| ASTM A29 |

4340 |

0.38-0.43 |

0.15-0.35 |

0.6-0.8 |

≤ 0.035 |

≤ 0.04 |

0.7-0.9 |

1.65-2.0 |

0.2-0.3 |

EN10250 |

36CrNiMo4 |

0.32-0.4 |

≤ 0.4 |

0.5-0.8 |

≤ 0.035 |

≤ 0.035 |

0.9-1.2 |

0.90-1.2 |

0.15-0.3 |

| 1.6511 |

BS 970 |

EN24 |

0.36-0.44 |

0.1-0.4 |

0.45-0.7 |

≤ 0.035 |

≤ 0.04 |

1.0-1.4 |

1.3-1.7 |

0.2-0.35 |

| 817M40 |

| JIS G4103 |

SNCM439 |

0.36-0.43 |

0.15-0.35 |

0.6-0.9 |

≤ 0.03 |

≤ 0.03 |

0.6-1.0 |

1.6-2.0 |

0.15-0.3 |

| GB 3077 |

40CrNiMoA |

0.37-0.44 |

0.17-0.37 |

0.5-0.8 |

≤ 0.025 |

≤ 0.025 |

0.6-0.9 |

1.25-1.65 |

0.15-0.25 |

3.Physical Property

| Density g/cm3 |

7.85 |

| Melting point °C |

1427 |

| Poisson's ratio |

0.27-0.30 |

| Machinability (AISI 1212 as 100% machinability) |

50% |

| Thermal expansion co-efficient µm/m°C |

12.5 |

| Thermal conductivity W/(m.K) |

44.5 |

| Modulus of elasticity 10^3 N/mm^2 |

210 |

| Electric resistivity Ohm.mm2 /m |

0.19 |

| Specific heat capacity J/(kg.K) |

460 |

Modulus of elasticity 10^3 N/mm2 |

100 ℃ |

200 ℃ |

300 ℃ |

400 ℃ |

500 ℃ |

| 205 |

195 |

185 |

175 |

165 |

Thermal expansion 10^6 m/(m.K) |

100 ℃ |

200 ℃ |

300 ℃ |

400 ℃ |

500 ℃ |

| 11.1 |

12.1 |

12.9 |

13.5 |

13. |

4. Mechanical Property

| Mechanical Condition |

T |

U |

V |

W |

X |

Y |

Z |

| Ruling Section (mm) |

150 |

100 |

63 |

30 |

30 |

30 |

30 |

| Tensile Strength Mpa |

850-1000 |

930-1080 |

1000-1150 |

1080-1230 |

1150-1300 |

1230-1380 |

>1550 |

| Yield Strength,Mpa |

≥665 |

≥740 |

≥835 |

≥925 |

≥1005 |

≥1080 |

≥1125 |

| Elongation % |

≥13 |

≥12 |

≥12 |

≥11 |

≥10 |

≥10 |

≥5 |

| Izod Impact J |

≥54 |

≥47 |

≥47 |

≥41 |

≥34 |

≥24 |

≥10 |

| Charpy Impact J |

≥50 |

≥42 |

≥42 |

≥35 |

≥28 |

≥20 |

≥9 |

| Brinell Hardness HB |

248-302 |

269-331 |

293-352 |

311-375 |

341-401 |

363-429 |

>444 |

5.High Temperature Strength

| For quenched and tempered heavy forgings |

Diameter mm |

Yield strength MPa |

| 20 ℃ |

100 ℃ |

200 ℃ |

250 ℃ |

300 ℃ |

350℃ |

400℃ |

| ≤250 |

590 |

549 |

510 |

481 |

441 |

412 |

371 |

| 250-500 |

540 |

505 |

471 |

451 |

412 |

383 |

353 |

| 500-750 |

490 |

466 |

441 |

422 |

392 |

363 |

343 |

6.Forging

Forging temperature should be carried out between 1150℃-1200℃,The lower the forging-ending temperature ,the finer the grain size .hold suitable time for the steel to be thoroughly heated before forge, but don’t forge below minimum forging temperature 850°C. AISI 4340 has good forging characteristics,but crack is easily occured when improper cooling way after forged,so it should be cooled as slowly as possible in still air or in sand after forged.

7.Normalizing

Normalizing is used to refine the structure of forgings that might have cooled non-uniformly after forged,and considered as a conditioning treatment before final heat treatment.Normalizing temperature for AISI 4340 steel should be carried out between 850℃-880℃. hold suitable time for the steel to be thoroughly heated to complete the ferrite to austenite transformation.Cool in still air.

8.Annealing

Full annealing is recommended for AISI 4340 before machining, AISI 4340 should be carried our at a nominal temperature of 830℃-850℃,hold suitable time for the steel to be thoroughly heated, then furnace cooling to 610℃ at a rate of 11℃ per hour, finally air cooling.

9.Hardening

This heat treatment will obtain martensite structure after quenched.It will increase the surface hardness and strength.AISI 4340 should be carried out between 830℃-865℃, hold suitable time for the steel to be thoroughly heated, soak for 10-15 minutes per 25 mm section, oil quench is recommended.Tempering should be followed immediately after quenched.

10.Tempering

AISI 4340 alloy steel should be in the heat treated or normalized and heat treated condition before tempering.Tempering is usually carried out to relieve stresses from the hardening process, but primarily to obtain the required hardness and mechanical properties. The actual tempering temperature will be chosen to meet the required properties.it is usually carried out at 450℃- 660℃,hold until temperature is uniform throughout the section, soak for 1 hour per 25 mm of section, and cool in still air.Tempering between 250℃-450℃ is not avoided as tempering within this range will seriously reduce the impact value,result in temper brittleness.

11.Application

AISI 4340 is often used in preference to AISI 4140 at the higher strength levels because of its better hardenability and improved CVN impact toughness.

Typical applications include:Heavy-duty axles, shafts, heavy-duty gears,spindles, pins, studs, collets, bolts, couplings,sprockets, pinions, torsion bars, connecting rods,crow bars, conveyor parts,forged hydraulic,forged steel crankshafts etc.

What Heat Treatment We Supply For AISI 4340 Steel

- Normalized(+N)

- Annealed(+A)

- Quenched & Tempered(+QT)

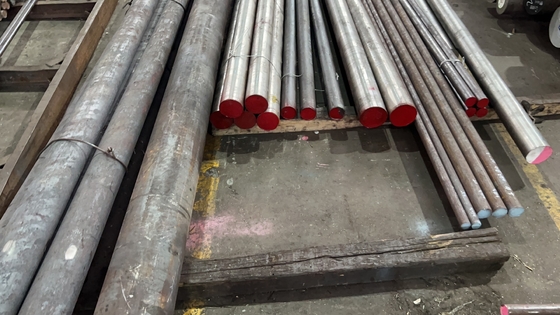

What Size We stock For AISI 4340 Steel

- Hot Rolled Round Bar:Φ18-Φ200mm,7 Days Delivery

- Hot Forged Round Bar:Φ140-Φ230mm,10 days Delivery

- Customized service:Special Size & Length,30 days Delivery

We Supply Free Sample of AISI 4340 Steel

Before you buy AISI 4340 Steel from us, you can try to get samples from us for Tesing and Evaluating.It’s just one way of us proving to you that our goal and our mission is to provide quality products!

In fact, if you need to buy AISI 4340 and 4140 steel, you can trust us! Our employees always maintain an open attitude and are willing to provide you with help and assistance!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!